Steeple Installed at St. Michael Church

Pawcatuck, CT

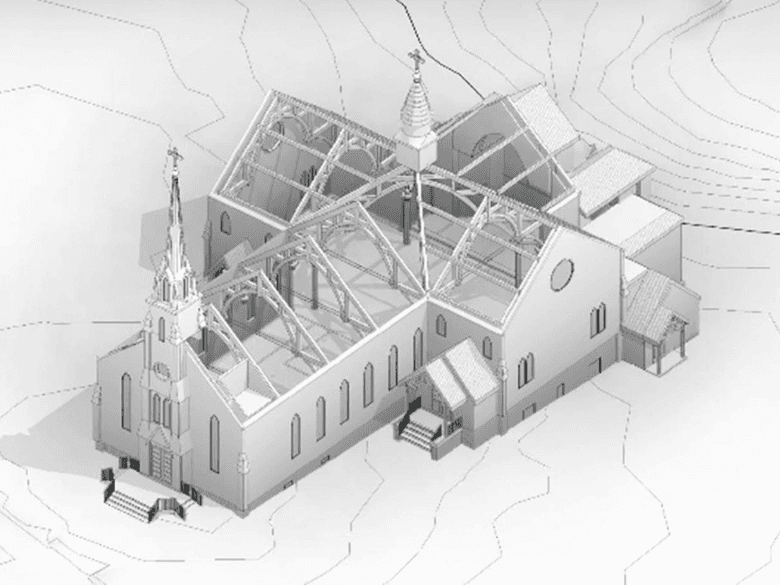

The Church of St. Michael the Archangel reached its next milestone this July with the installation of its new steeple. The steeple is a reconstruction of the original steeple based on archival photos of the civil-war era Church. The original steeple blew off the Church shortly after it was built, making its reconstruction an integral component of this Project.

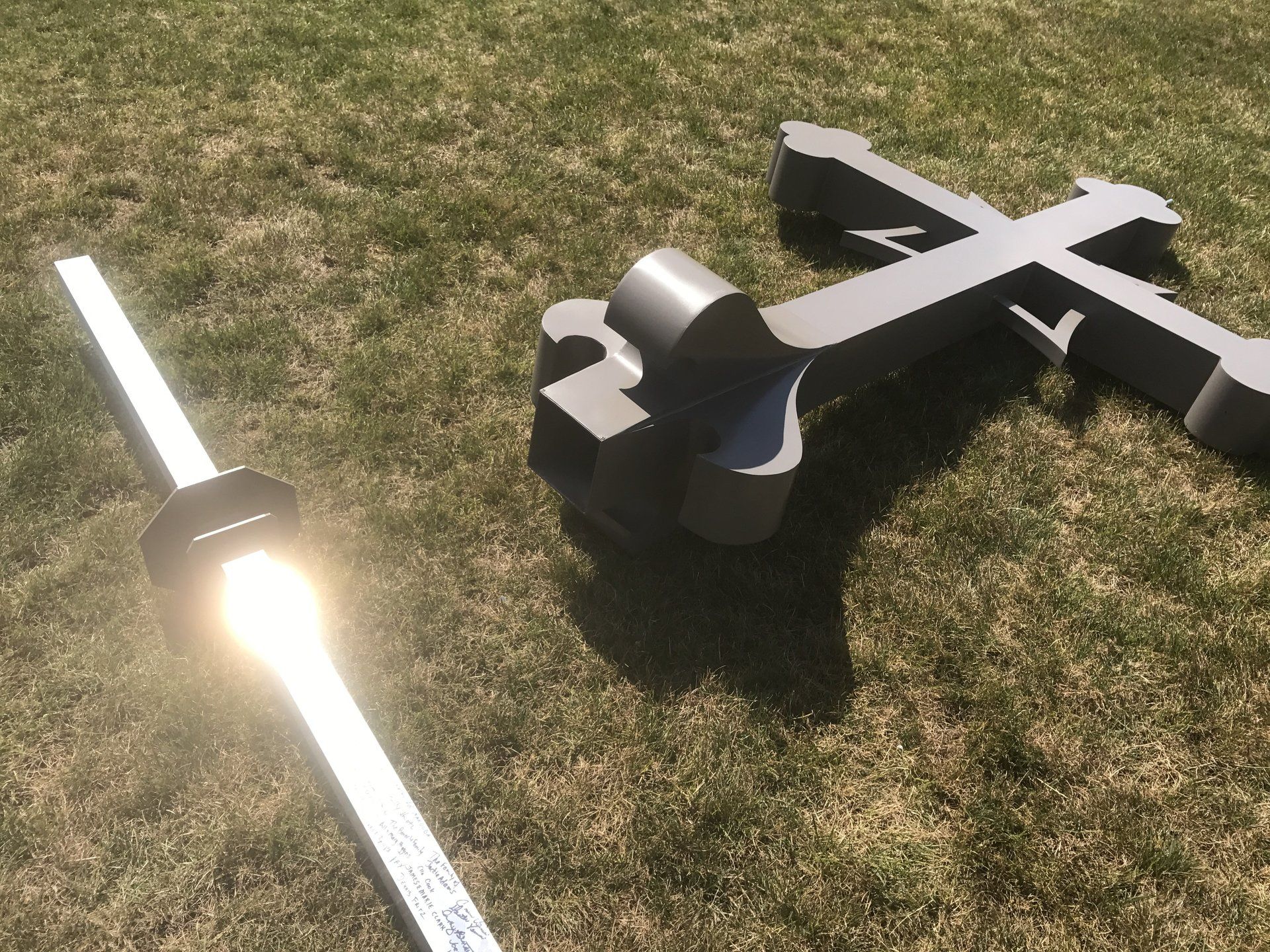

The steeple is anchored to the structure with a series of bolts fastened through the octagonal base of the steeple and an octagonal angle frame designed by GNCB. The steeple is braced with chevron braces within its square base which is constructed with structural steel designed to accommodate the replicated tapering of the original steeple.

Phase 1 of the reconstruction of St. Michael Church will soon be completed. In addition to the installation of the steeple, the cold-formed steel shear walls are close to completion as the exterior cladding and stained glass windows are being installed. The east and west entrances and rear additions are in progress. Phase 2 of the project will include the interior fit-out and finishing of the Church.

This marks the second major milestone in the reconstruction of St. Michael. The first milestone, the raising of the first timber truss , was celebrated by the Parish with a truss-raising ceremony during which Bishop Michael Cote of the Diocese of Norwich blessed the first truss before its installation.

Architect: Geddis Architects

Construction Manager: Petra Construction

Steeple Fabricator: Campbellsville Industries, Inc.

Watch the videos of the steeple and cross installation.