Updates from GNCB

By websitebuilder

•

January 2, 2024

After over 50 rewarding years of geotechnical engineering practice, the last 28 of which were with GNCB as an Associate, David Freed retired on December 31, 2023. In 1995, David established the geotechnical engineering practice that provided many of GNCB’s clients, as well as his core clients, an integrated engineering service in foundation design. David’s presence both enhanced the structural engineering staff with a greater understanding of geotechnical theory and practice as well as provided the firm’s clients with a fortuitous combination of structural and geotechnical engineering services that lasted throughout the project. David’s experiences at GNCB provided the basis for his paper “Benefits of In-House Collaboration of Geotechnical and Structural Engineering Services” that appeared in the 2008 Geotechnical Special Publication No. 180 that honored his University of Florida professor, Dr. John Schmertmann. David’s geotechnical work crossed a wide range of projects and foundation types; he developed an expertise in resolving construction problems. He will be greatly missed at the firm, but please join us in wishing David all the best in his retirement.

By GNCB

•

May 6, 2022

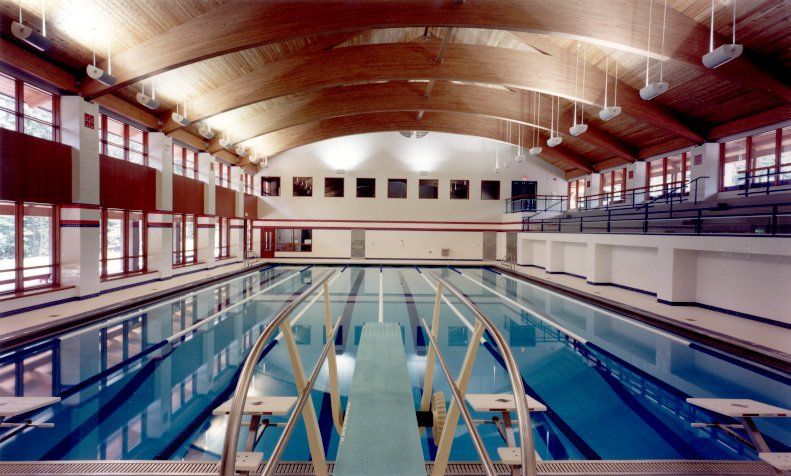

GNCB has provided geotechnical and structural engineering services for many commercial pools for public and private owners during our over 50 years of practice. Our dedicated team of professional engineers works with architects and owners to advance the design of pools and to increase the lifespan of these unique structures. Fluctuations in water levels, possible unsuitable soils and water infiltration are all factors that must be considered. Commercial pools typically consist of a reinforced concrete mat with cantilever concrete sidewalls that are keyed into the mat. A design factor that is sometimes overlooked is that many commercial pools are completely drained of water during the harsh winter months. Perimeter concrete walls are designed as retaining structures to accommodate this condition. GNCB’s initial step in the design of commercial pools is to undertake a subsurface exploration program in order to understand subsurface conditions. While in many instances, the soils at mat bearing grade are suitable to directly support the mat, test boring data can reveal unsuitable soils that may require pile foundations and/or improvement of the unsuitable soils to make them acceptable to support a mat foundation. In addition, groundwater levels need to be documented so that a design for hydrostatic uplift can be anticipated. Regardless of the type of pool foundation, it is important to understand the type of soil directly below the pool, so that proper consideration can be given to design for frost susceptibility. For the case of a drained pool during periods of winter freezing, the presence of a frost susceptible soil, and possible groundwater near the bottom of pool, may result in foundation heave leading to cracking of the foundation. Structural design of the pool requires conventional cantilever concrete sidewalls. Reinforcing in the wall and design of the concrete mix needs to be sufficient to prevent cracking and wall movement, for both cases of the pool being empty and filled. In addition, water stops at the interface between the wall and mat, and at cold joints within the wall are essential to prevent outside water infiltrating the pool or loss of pool water. The use of a rigid concrete wall enables the precise setting of a perimeter gutter assembly around the pool. Engineers at GNCB can help in your pool design with an assurance that it will survive the many years of use. For comprehensive services that offer value and integrity from a team you can trust, GNCB Consulting Engineers, P.C. provides a unique blend of structural, geotechnical, and historic preservation needs.

By GNCB

•

April 13, 2022

GNCB Consulting Engineers, P.C. in Old Saybrook, CT has helped to reconstruct the faltering retaining walls that comprise the Connecticut waterfront. Our dedicated team of professional geotechnical and structural engineers have many years of experience in this rebuilding effort. With over 50 years of engineering experience, including historic preservation work, GNCB is able to solve the many problems that plague our waterfront. Regardless of the rebuilding effort needed, the first step is to secure the necessary design and building permits from both the Connecticut Department of Environmental and Energy Protection (CTDEEP) and the Army Corps of Engineers (ACE). For the most part a permit is needed prior to starting any construction and/or repair work; there is, however, an expedited procedure to complete emergency repairs ahead of securing a permit. The initial part of the permit and design process involves a test boring program to determine subsurface conditions. These conditions likely consist of some surface man-placed fill and organic soils underlain by overburden sand and or glacial till. In some instances, the surface overburden soils may be directly underlain by bedrock. Borings may be drilled from land or from the water, the latter requires special barge equipment. Retaining walls typically consist of steel sheet piling, reinforced concrete, or gravity stone walls. Selection of a suitable wall type often depends on the specific geometry of the wall/waterfront, the depth of free water on the outboard side of the wall, and the depth to suitable bearing soil. The reinforced concrete wall and stone walls have some overall height limitations, something in the range of 20 ft. or less. While steel sheet pile walls can serve higher depths, a system of tiebacks or anchor system is needed to keep the wall laterally stabilized. Steel sheet pile walls can be made very stiff with the integration with heavy steel H piles; this stiff pile permits greater wall heights without the need for lateral anchor support. Regardless of the wall type used, particularly for reinforced concrete and stone gravity walls, some degree of erosion protection is needed for those walls in a high hazard zone, per FEMA regulations and mapping. Engineers at GNCB can help in your permitting and design to rebuilding a waterfront retaining wall on your property with an assurance that it will survive the harsh storm events that can endanger our area. For comprehensive services that offer value and integrity from a team you can trust, GNCB Consulting Engineers, P.C. provides a unique blend of structural, geotechnical, and historic preservation needs.

By GNCB

•

March 1, 2022

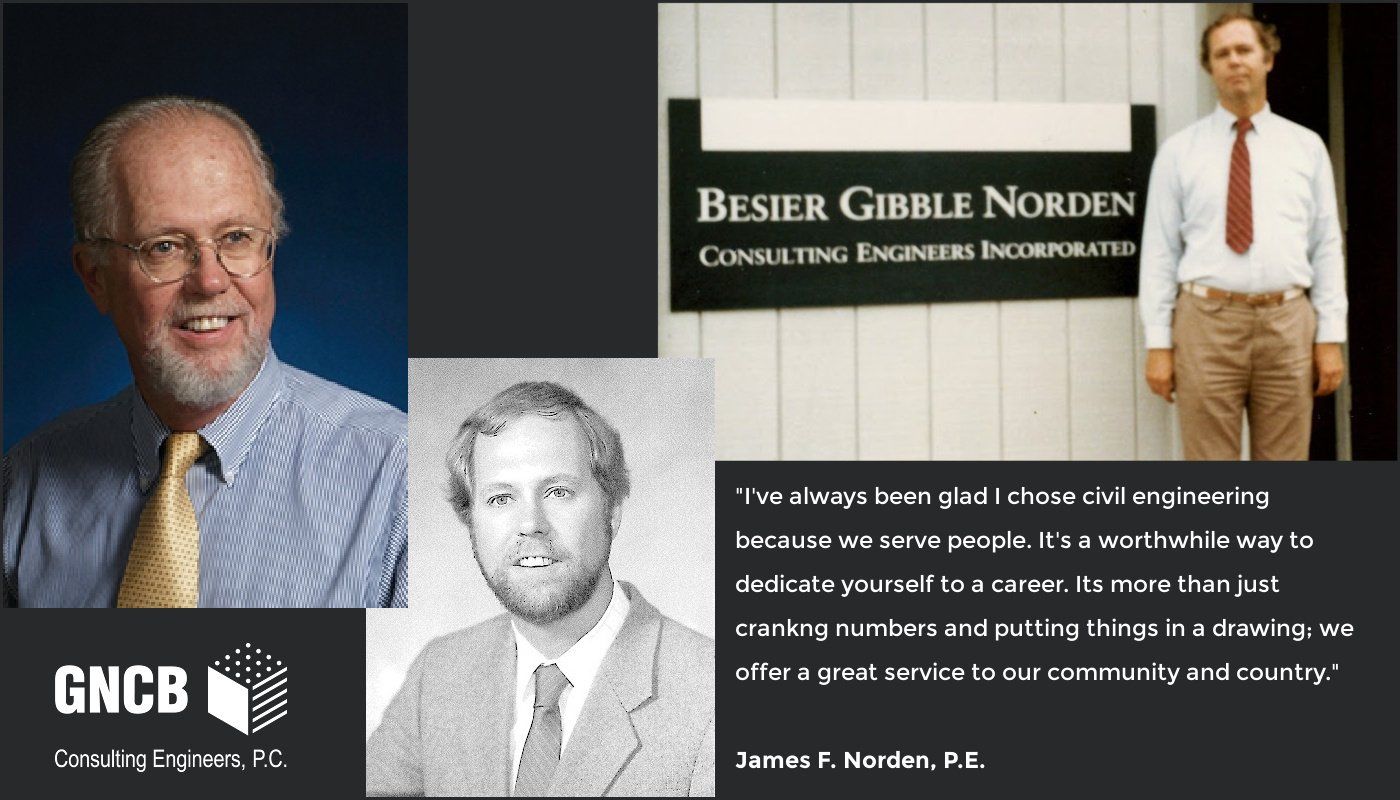

After 54 years of Structural Consulting Engineering, we are both happy and sad to announce the well-deserved retirement of James Norden on January 14, 2022. He has been an outstanding addition to GNCB for the past 46 years, forty of those years as a partner in the firm. Jim was instrumental in developing our Historic Preservation department in 1995 and has mentored our next generation of engineers in this field. His structural engineering career spans across the United States and serves a variety of sectors including cultural, institutional, religious, residential, and specialty structures. Jim's Historic Preservation experience includes projects involving over 50 sites on the National Register of Historic Places, as well as a number of National Landmark sites.

By GNCB

•

February 26, 2021

Many members of the GNCB team enjoy traveling nationally and internationally. The cause of each member’s wanderlust varies from the joy of long motorcycle rides, to the desire to learn about different cultures, to the love of international food. However different our trips are, we all find joy in seeing historic landmarks and new construction in the places we visit. After almost a year of restricted travel, our team is joyfully reminiscing about past trips and joyfully looking forward to future adventures. We hope you enjoy this new series about GNCB’s Traveling Engineers.