Major Milestone in Reconstruction of St. Michael Church

Pawcatuck, CT

The Church of St. Michael the Archangel celebrated a major milestone in construction this April with the installation of the first timber truss. To commemorate this point in construction, the Church invited the St. Michael community and the project design and construction teams to attend a ceremony in which Bishop Michael Cote of the Diocese of Norwich blessed the first truss before its installation.

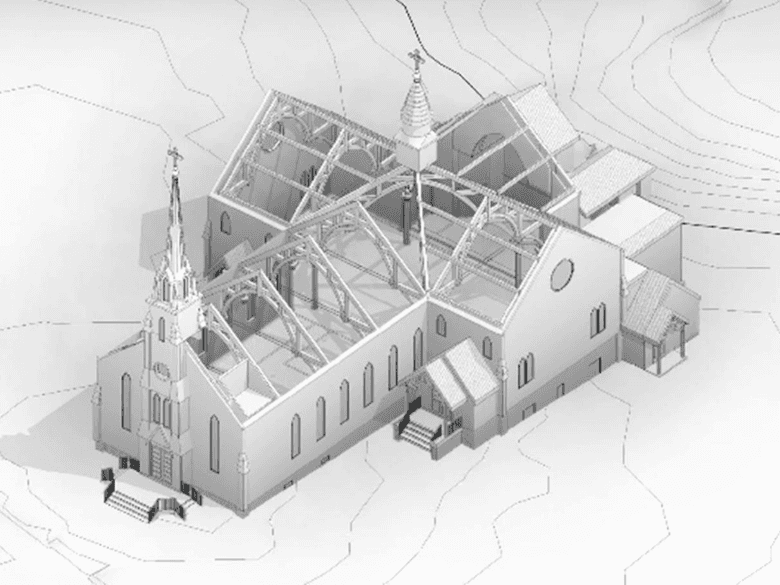

The parish decided to reconstruct their Church following GNCB’s discovery of extensive failures in the original Church’s scissor roof trusses in spring 2012. The new Church is designed to replicate the original’s layout and appearance, while providing major improvements to accessibility, community space, and aesthetics.

As Engineer-of-Record for this project, GNCB is responsible for the improvements and modifications to the existing foundations, reinforcement of the first floor framing, design of the lateral system of the Church using cold-formed-steel construction, and design of the Church balcony and rear addition. To-date, installation of concrete and steel in the lower level of the Church is complete. Construction now moves above ground with the installation of steeple steel and the timber trusses.

See the photos and video below to learn more about this project’s backstory and progress as well as the Truss Blessing Ceremony.

Architect: Geddis Architects

Construction Manager: Petra Construction

Timber Frame Designer and Contractor: Vermont Timber Works