Wood Cantilever Repair of National Register House using ConServ Epoxy

Orange, CT

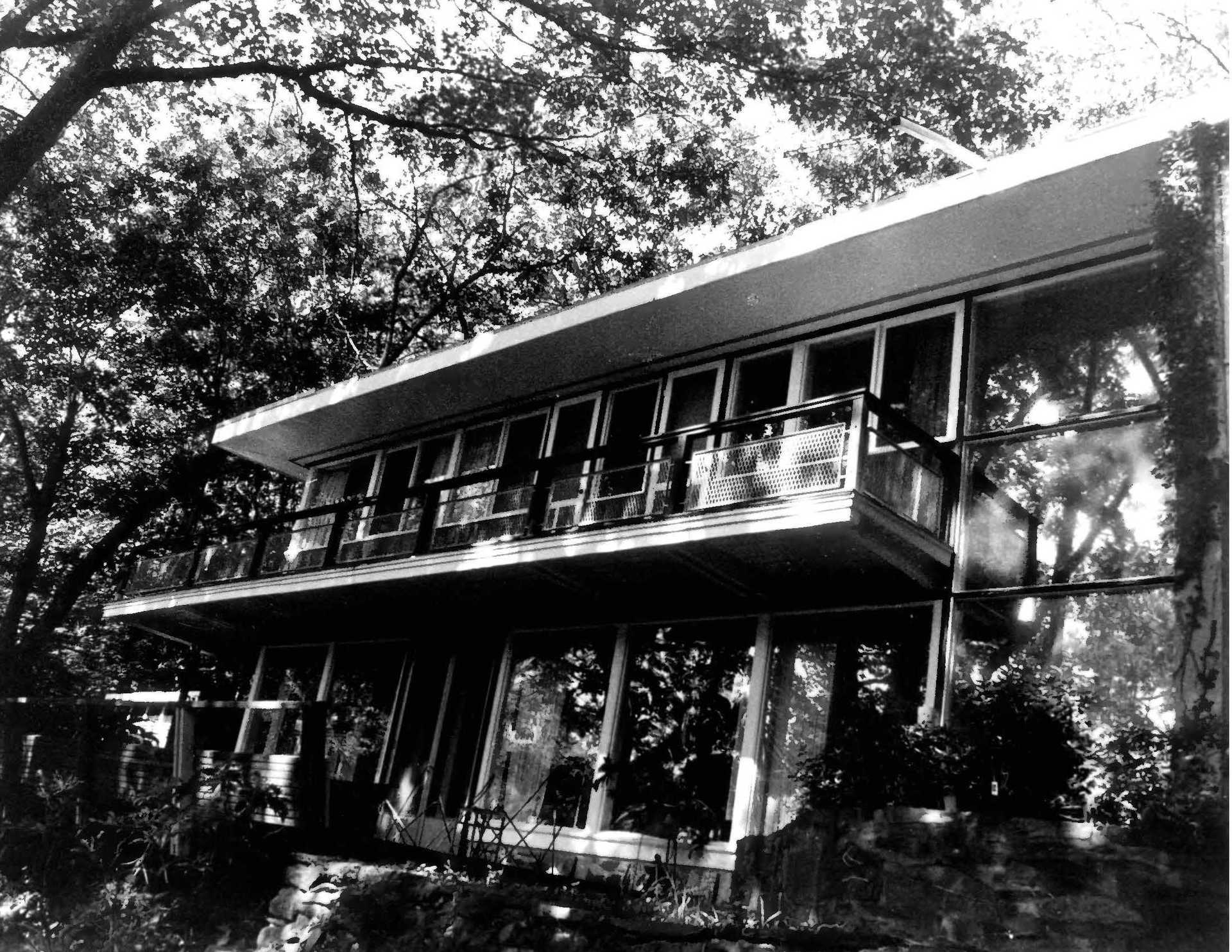

The reconstruction of the second floor balcony around the perimeter of 30 Derby Avenue in Orange, CT was recently completed. 30 Derby Avenue, also known as the Henry F. Miller House, is an example of international style architecture and is on the National Register of Historic Places. The second floor balcony, which was severely deteriorated due to water infiltration, exemplifies three characteristics of international style architecture including the integration of structure and site, taking advantage of the climate, and providing simple aesthetic features. GNCB provided a condition assessment, construction documents, and construction administration for this project which reestablished the balcony structure and perimeter railing.

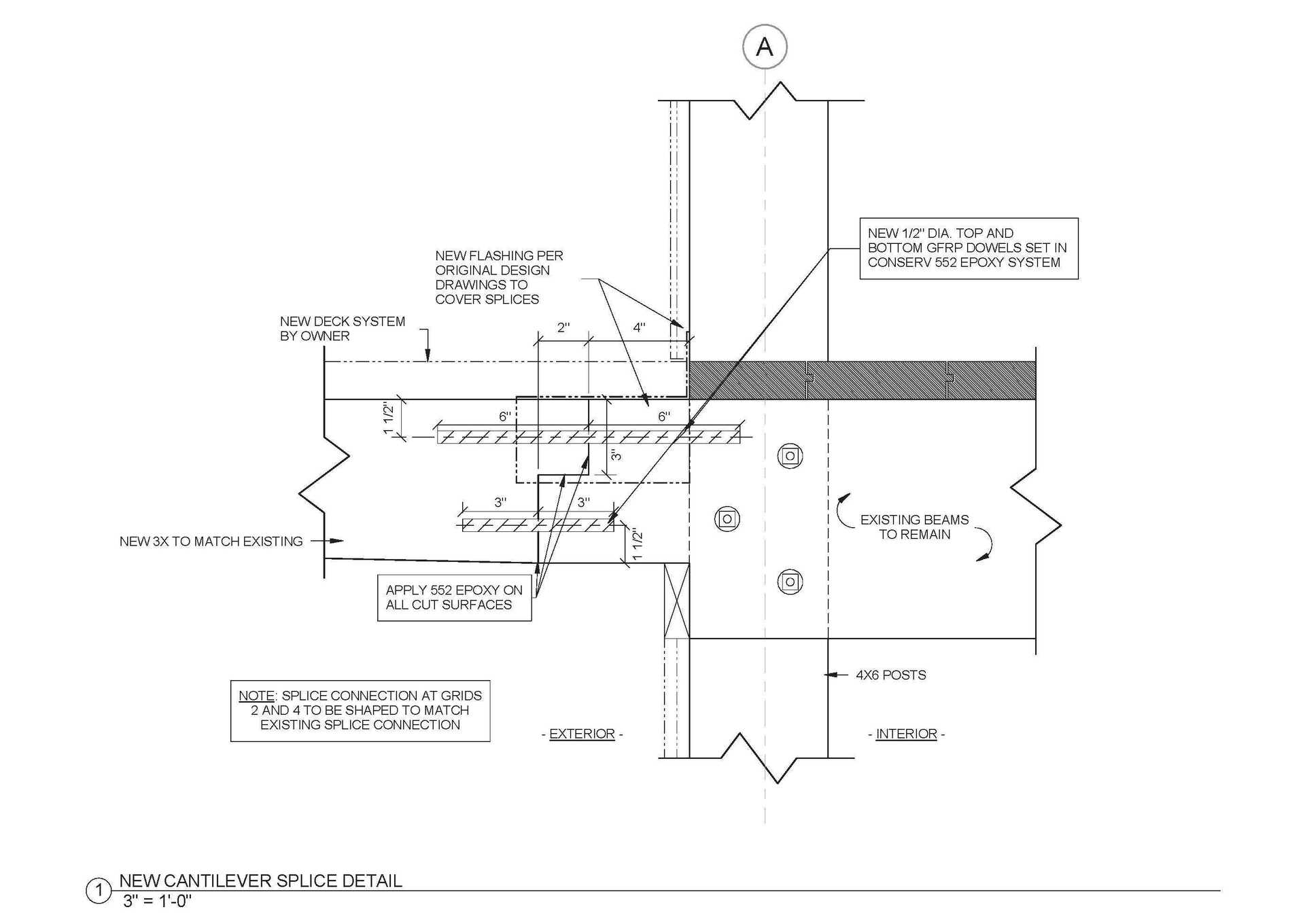

The damaged double-cantilever structure of the balcony was reestablished using glass fiber-reinforced polymer (GFRP) rebar and a ConServ Epoxy restoration system. The damaged cantilevers were cut back an acceptable surface and the GFRP bars were doweled into the existing timbers and the new timbers. The bars and timber faces were prepared using ConServ 552 Epoxy, a multipurpose structural epoxy adhesive. Paul Marlowe of Marlowe Restorations LLC and the owner of ConServ Epoxy LLC, conducted the cantilever reconstruction process. The railing design by Christopher Williams Architects replicated the original railing from available photographs.

Architect: Christopher Williams Architects, LLC

Contractor: Marlowe Restoration LLC

Supplier: ConServ Epoxy LLC